If you’re like most people, you use an air compressor for a variety of tasks around the house or shop. Whether you’re spraying paint, powering a nail gun, or inflating tires, it’s important to have plenty of CFM (cubic feet per minute) available to get the job done quickly and efficiently. Here are some tips on how to increase air compressor cfm.

There are a lot of things to consider when purchasing an air compressor. One of the most important factors is the CFM rating. This number tells you how much air the compressor can produce in one minute. If your needs exceed the CFM rating of the compressor, you’ll need to purchase a larger model. So keep reading to know more!

Why is It Important to Increase Air Compressor Cfm?

Having a higher CFM rating on your air compressor means that the unit is capable of handling more air volume in a shorter amount of time. This is important because it allows you to use your air tools more efficiently without having to wait for the unit to catch up.

Otherwise, you would be waiting around a lot more often for your air compressor to fill up the tank and build back up to pressure. So it is important to choose an air compressor with a CFM that is appropriate for the types of air tools that you will be using.

13 Best Ideas About How to Increase Air Compressor Cfm

There are a few ways to increase the CFM output of your air compressor. Some of these methods may require you to invest in additional tools or equipment, while others can be accomplished with just a few minor adjustments. Either way, increasing your air compressor’s CFM will allow you to get more work done in less time and can be a great way to improve your efficiency and productivity.

1. Check the Air Filter

One of the most common reasons for a decrease in CFM output is a dirty air filter. Over time, debris and dust can accumulate on the filter, restricting airflow and causing your compressor to work harder to produce the same amount of air. Checking the air filter regularly and replacing it when necessary is an easy way to ensure that your compressor is operating at peak efficiency.

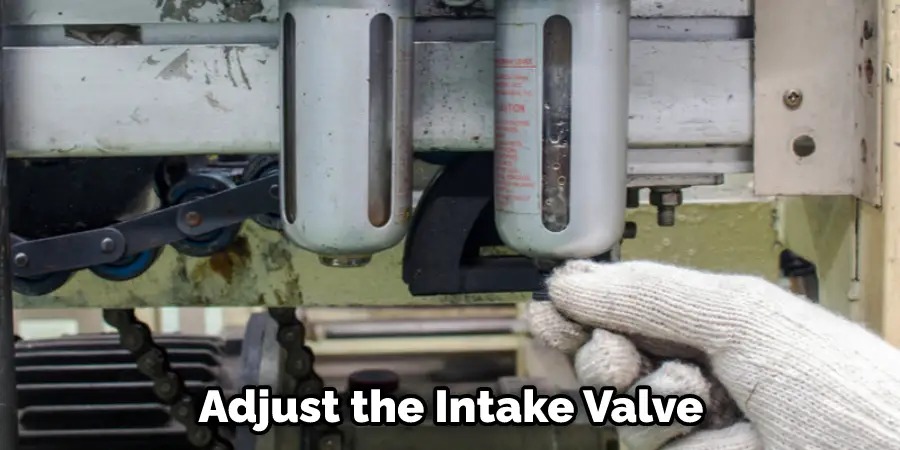

2. Adjust the Intake Valve

Another potential reason for decreased CFM output is an obstructed intake valve. This can happen if the valve becomes clogged with debris or if it isn’t opening and closing properly. Cleaning or replacing the intake valve is typically a quick and easy fix that can dramatically improve your compressor’s performance.

3. Invest in a High-Performance Air Compressor

If you’re looking for a more long-term solution, investing in a high-performance air compressor can be a great way to increase your CFM output. These units are designed to deliver superior airflow and often come with features like an enhanced intake system and larger motors. While they may come with a higher price tag, they’ll provide you with the increased CFM output you need to power your tools and get the job done right.

4. Use a Smaller Diameter Air Hose

If you have a large air compressor, you might be tempted to use a larger diameter hose to get more airflow. However, this will actually decrease the CFM of your air compressor. A larger diameter hose will cause more friction and resistance, which will slow down the airflow. Instead, use a smaller diameter hose that has less friction and resistance. This will help to increase the CFM of your air compressor.

5. Use a Shorter Air Hose

If your air compressor is located far away from where you’ll be using it, the air has to travel a long way through the hose before it gets to your tools. This can cause a significant drop in pressure by the time the air reaches your tool. To avoid this, use a shorter air hose. This will help to keep the air pressure high and maintain CFM.

6. Reduce the Number of Air Tools Being Used

In the case of using multiple air tools at the same time, it can cause your air compressor to work harder than necessary and decrease its cfm output. Try to use only one air tool at a time or, if possible, invest in a second air compressor so that each one isn’t working as hard.

7. Use a More Efficient Air Tool

If you have an air tool that isn’t working as efficiently as it could be, it can actually drain a lot of CFM from your compressor. You might not think that one air tool would make that big of a difference, but if you’re using an older or less efficient model, it can really add up. Investing in a more efficient air tool can make a big difference in your overall CFM output.

8. Use an Air Regulator

By using an air regulator, you can help to increase the CFM of your air compressor. This is because the air regulator will help to release the pressure in the tank, which will then allow more air to enter the tank. It can be difficult to find the right air regulator for your compressor, so it is best to consult with a professional before purchasing one.

9. Increase the Tank Size

Another way to increase the CFM of your air compressor is to increase the size of the tank. This is helpful if you find that your air compressor is constantly running out of air and you need to frequently stop what you’re doing to let it catch up.

A larger tank will store more air and allow your compressor to run for longer periods of time without needing to stop. It might be expensive to upgrade to a larger tank, but it will be worth it in the long run if you use your air compressor frequently.

10. Check the Discharge Temperature

High discharge temperature will reduce the capacity of the air compressor. Check the manufacturer’s recommendations and make sure that your discharge temperature is within the ideal range. You may need to install a cooling system to help lower the discharge temperature if it is too high.

11. Upgrade the Pump

If you have an older air compressor, it may be time to upgrade the pump. Newer air compressors often have better pumps that can provide more CFM. This is something to consider if you have an older model air compressor.

12. Use Larger Piping

If your air compressor is connected to small diameter piping, this can restrict the airflow and cause a drop in CFM. Make sure that the piping you are using is of a sufficient size to allow proper airflow. You may need to upgrade your piping if it is too small.

13. Use a Synthetic Air Compressor Oil

In case of using a petroleum-based air compressor oil, switch to synthetic oil. Synthetic oils have lower viscosity and will not cause as much of a drop in CFM as petroleum-based oils. It can be more expensive to use synthetic oils, but it may be worth it if you are having issues with CFM.

Things That You Need to Take Into Consideration Before You Start Increasing the Cfm

1. The Power of the Machine

You need to be aware that the power of your machine is determined by how much air it can pump out. If you want to increase the cfm, you need to increase the power first. This will also ensure that your motor will not overheat.

2. The Capacity of the Tank

The size of the tank will also affect how much air your compressor can deliver. If you have a smaller tank, you might need to increase the pressure in order to get more air out of it. This will also help prevent your motor from overheating.

3. The Type of Compressor

There are two types of compressors: single-stage and two-stage. The two-stage compressor is more powerful and can deliver more air. However, it is also more expensive. If you only need a little extra cfm, then the single-stage compressor will be sufficient.

4. The Quality of the Compressor

The quality of the compressor also affects how much air it can deliver. If you buy a cheap compressor, it will not last as long, and it will not be able to deliver as much air.

5. The Location of the Compressor

The location of the compressor also matters. If it is in a hot area, it will not be able to deliver as much air. This is because the heat will cause the air to expand, which reduces the amount of air that the compressor can deliver.

Conclusion

If you are trying to figure out how to increase air compressor CFM, there are a few things that you can do. By following the tips in this article, you should be able to get your air compressor working at its best and providing the most CFM possible.

If you have any questions or need assistance, our team of experts would be happy to help. Give us a call today, and we will be more than happy to assist you in getting your air compressor working better than ever before.