Shiplap is a famous wall covering choice due to its rustic look and relative ease of installation. However, one of the biggest challenges with shiplap is figuring out how to cut outlet holes that are both neat and consistent. This blog post will provide step-by-step instructions on how to cut outlet holes in shiplap and achieve professional-looking results. Keep reading to learn more!

What Causes Gaps in Shiplap

There are a few reasons why you might see gaps in your shiplap. The first is that the boards are not of uniform thickness. This is not necessarily a problem, but it can make it more difficult to get a tight fit when you’re installing the shiplap. The second reason is that the boards may have warped over time.

If this is the case, you may need to use a pry bar or other tool to straighten the boards before installing them. The third reason is that the boards may not be properly nailed or screwed into place. This can cause them to shift and create gaps.

Additionally, gaps can occur if the boards are not cut correctly. If the cuts are too shallow, the boards will not fit together snugly, and gaps will appear. If the cuts are too deep, the boards will not sit flush with the wall, and gaps will also appear. Another common cause of gaps is when the wall itself is not level.

If the surface is uneven, the boards will not fit together properly, and gaps will appear. Lastly, gaps can also be caused by expansion and contraction due to changes in temperature and humidity.

Why Do Outlet Holes Need to Be Cut?

Outlet holes need to be cut for two reasons. The first is that outlets are not always placed in the ideal spot for shiplap. The second is that outlets need to be recessed in order to sit flush with the wall. This is because shiplap boards are usually thicker than standard drywall. As a result, the outlet box will stick out if it is not recessed.

Another reason why outlet holes need to be cut is that they need to be a certain size in order to accommodate the outlet cover plate. The cover plate needs to be able to snap into place, and this can only happen if the hole is the correct size. Finally, the outlet box itself needs to be able to fit inside the hole. If the hole is too small, the outlet box will not fit, and if the hole is too big, the outlet box will be loose and could potentially fall out.

Some Easy Ways How to Cut Outlet Holes in Shiplap

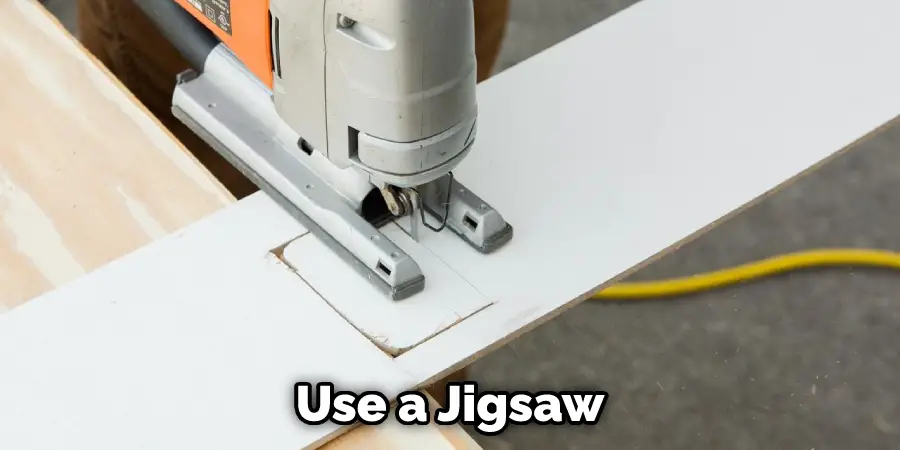

1. Use a Jigsaw

If you have a jigsaw, you can use it to cut outlet holes in a shiplap. This is the best method to use if you need to cut multiple holes or if the holes are not perfectly straight. First, mark the outline of the hole on the shiplap. Then, use a drill to create a starter hole at one end of the outline. Next, insert the jigsaw blade into the starter hole and begin cutting along the outline.

When you reach the other end of the outline, cut slowly and carefully so that you don’t veer off course. Finally, use a file or sandpaper to smooth out the hole’s edges. It’s important to use a blade that is designed for cutting wood, and you’ll also need to use a guide. If you don’t have a guide, you can clamp a piece of scrap wood to the shiplap to act as a makeshift guide.

2. Use a Hole Saw

If you don’t have a jigsaw, you can use a hole saw to cut outlet holes in a shiplap. A hole saw is a type of drill bit with a circular cutting edge. It’s important to use a hole saw that is the same size as the outlet box. Otherwise, the outlet box won’t fit. To use a hole saw, first, drill a pilot hole in the center of the outlet hole.

Then, attach the hole saw to your drill and drill around the perimeter of the outlet hole. Be sure to go slowly and apply steady pressure, so the hole saw doesn’t wander. Finally, use a sharp knife to clean up any rough edges. If you’re uncomfortable using a hole saw, you can always ask a friend or neighbor for help.

3. Use a Router

If you have a router, you can use it to cut outlet holes in the shiplap. This is the best method to use if you need to cut multiple holes. First, mark the center of each hole on the shiplap. Then, set the router to a shallow depth and make a series of passes over the marked area. Be sure to wear eye and ear protection while using a router. You can use a drill to make the holes if you don’t have a router.

4. Use a Dremel Tool

If you have a Dremel tool, you can use it to cut outlet holes in the shiplap. This is the best method to use if you want to avoid damaging the shiplap. First, mark the outlet’s location on the shiplap using a Dremel tool. Then, use the Dremel tool to cut a hole in the shiplap. Be sure to wear safety glasses when using a Dremel tool.

5. Use an Oscillating Tool

If you have an oscillating tool, you can use it to cut outlet holes in a shiplap. This is a great option if you don’t want to deal with the mess of sawdust. To use an oscillating tool, mark the outline of the outlet on the shiplap. Then, set the tool to a low speed and make slow, careful cuts along the outline. Be sure to wear ear and eye protection when using an oscillating tool. Avoid cutting too deeply, as you don’t want to damage the wall behind the shiplap.

6. Use a Reciprocating Saw

If you have a reciprocating saw, you can use it to cut outlet holes in the shiplap. This is a quick and easy way to do it, and it will give you a clean cut. First, mark the outline of the hole on the shiplap. Then, use the saw to cut along the outline. Be sure to wear safety glasses when using the saw. Be sure to cut slowly and carefully so that you don’t damage the shiplap.

7. Use a Coping Saw

If you have a coping saw, you can use it to cut outlet holes in the shiplap. This is a great option if you need to make a lot of cuts or if you need to make precise cuts. To use a coping saw, mark the outline of the outlet hole on the shiplap. Then, use the saw to cut along the outline. Be sure to go slowly and be precise. If you make a mistake, it will be very difficult to fix.

8. Use a Keyhole Saw

Another option for cutting outlet holes in shiplap is to use a keyhole saw. This is a small, hand-held saw specifically designed to cut small holes. To use a keyhole saw, first mark the outline of the hole with a pencil. Then, use the saw to cut along the outline of the hole. Be sure to go slowly and carefully so that you don’t accidentally cut too much. Once the hole is cut, you can use a chisel to clean up any rough edges. Finally, use sandpaper to smooth out the hole.

9. Use a Hacksaw

The hacksaw is one of the most versatile tools and can be used to cut anything from metal pipes to plastic. It can also be used to cut holes in a shiplap. The first thing you need to do is to make a template of the hole. You can use a piece of cardboard or any other stiff material. Cut the template out and then trace it onto the shiplap.

Next, use a sharpie or any other marker to mark the cutting line. Make sure that the line is visible. Now, take the hacksaw and start cutting along the marked line. Cut slowly and carefully. Once you are done, remove the excess shiplap using a chisel.

Tips and Warnings on How to Cut Outlet Holes in Shiplap

Tips:

- Make sure to use a sharp blade when cutting.

- Cut slowly and carefully to avoid chipping the wood.

- Use a guide (such as a level or straight edge) to help you cut straight lines.

- Sand the edges of the holes smoothly after cutting.

Warnings:

- Be careful when cutting – shiplap is a thin and delicate material.

- Always wear safety goggles when cutting wood.

- Keep children and pets away from the area while you are working.

- Do not attempt to cut holes in the shiplap without the proper tools and safety equipment.

Conclusion

So there you have it – a few different ways how to cut outlet holes in shiplap. Follow these tips, and you’ll be able to do it like a pro! We hope you found this article helpful. If you have any questions or comments, please feel free to leave them below. Thanks for reading!